| Model | DYJ-3 | DYJ-5 | DYJ-10 | DYJ-20 | ||||

| Production capacity | 1-3 | 3-5 | 5-10 | 10-20 | ||||

| Linear speed of filter belt | 5 | 5.7 | 7.95 | 6.3 | ||||

| Main drive speed | 11 | 9.5 | 11 | 8.2 | ||||

| Monitor rate | 1.5 | 3 | 4 | 5.5 | ||||

| Flushing pump power | 11 | 7.5 | 15 | 30 | ||||

| Flushing pump flow | 50 | 16 | 16 | 32 | ||||

| Washing pump head | 32 | 94 | 189 | 378 | ||||

| Reflux pump power | 2.2 | 5.5 | 5.5 | 5.5 | ||||

| Reflux pump flow | 12.5 | 25 | 25 | 25 | ||||

| Reflux pump head | 20 | 32 | 32 | 32 | ||||

| Power of cloth wheel | 0.37 | 0.37 | 0.37 | |||||

| Compressed air consumption | 1m3/h | |||||||

| Compressed air pressure | 0.6MPa | |||||||

| Inlet height | 1160 | 1840 | 2045 | 1920 | ||||

| Press belt size | 7780×800 | 11170× 1200 | 14300×1750 | 16800×2500 | ||||

| Dimensions | 3100×1475×1820 | 3940×2085×2430 | 5000×2780×2560 | 5420×3430×2420 | ||||

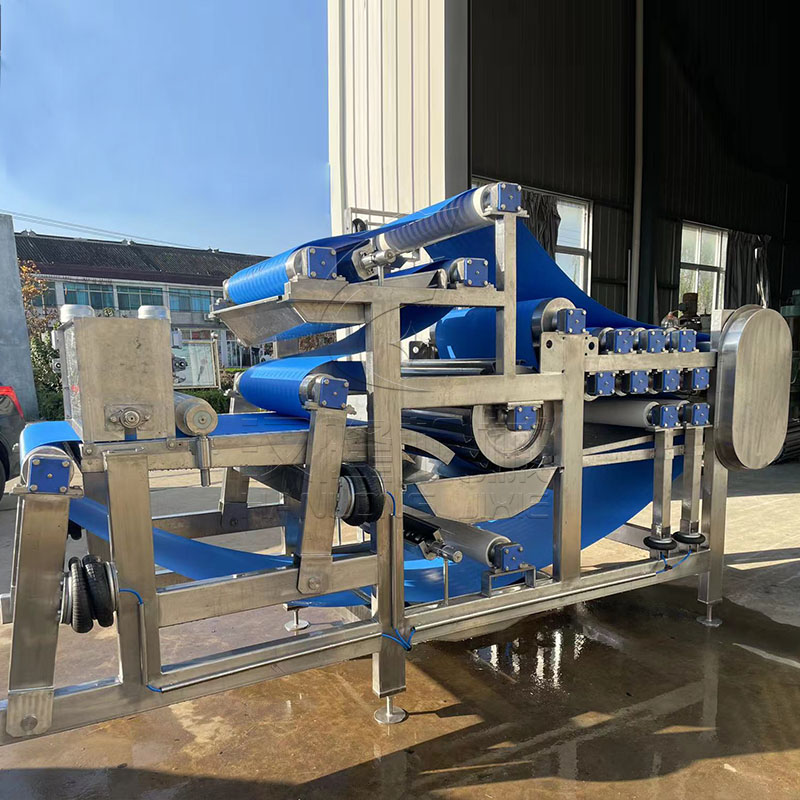

Working principle: The main engine consists of frame, upper and lower drive shafts, reducer assembly, filter press belt, cleaning belt assembly, feeding assembly, distribution device, fastening device, belt correction device, pressure device, protection device, pneumatic It is composed of electrical control device, cleaning water filter device, etc. The supporting equipment includes water filter device (including arc filter, water storage tank), stainless steel vertical multi-stage pump, water jet return pump, etc. The refined raw material (solid-liquid mixture) is composed of screw The pump is continuously pumped into the hopper (the material occupied bandwidth is adjustable), and the distribution rollers are evenly distributed. In the downwardly curved wedge-shaped area, a large amount of water is slowly forced out, forming a squeezed filter cake. In the press area, a drum with an "L" belt presses the water out, ensuring that it overflows quickly from both sides.