Customized according to customer needs

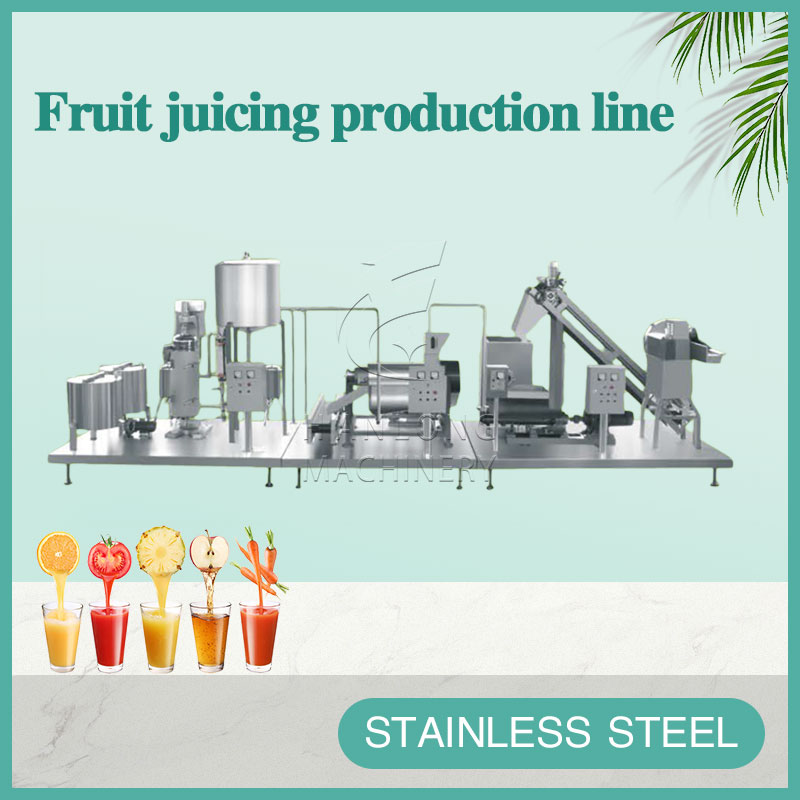

Process flow of fruit juice beverage production line:

1. Fruit Juicing: After the fruit is cleaned, it is squeezed by a juicer. Under normal circumstances, the juice extraction method in the juice beverage production line is to use external mechanical extrusion force to extrude fruit and vegetable juice from fruit and vegetable or fruit and vegetable pulp to obtain juice. Depending on the temperature of the raw materials during juicing, pressing can be divided into cold pressing, hot pressing and even freezing pressing.

2. Extraction: The extraction in the juice beverage production line is the process of transferring the juice in the fruit to the liquid extraction medium (hot water). It is mainly used for the extraction of fruit and vegetable raw materials (such as hawthorn) juice with low moisture content such as sour jujube, ebony, red jujube, etc. The extraction method is divided into static extraction, countercurrent extraction, one-time extraction method, multiple extraction method, etc. The factors affecting the juice yield of the extraction method mainly include extraction temperature, time, degree of crushing of raw materials, concentration difference, flow rate and so on.

3. Beating: The beating of the fruit juice beverage production line is to scrape and grind the broken fruit and vegetable raw materials through a beater and separate the fruit core, fruit seed, thin skin, etc. to obtain the fruit (vegetable) puree. The fineness of the puree can be achieved by selecting different apertures of the beater screen. In the processing of fruit and vegetable juice, this method is suitable for the production of fruit and vegetable pulp and pulp drinks, such as strawberry juice, mango juice, peach juice, hawthorn juice, etc. After the fruit and vegetable raw materials are crushed, they need to be pre-cooked in a pre-cooking machine immediately to passivate the activity of enzymes in the fruit and vegetables to prevent browning, and then be beaten. Generally, three beating processes are carried out in production. quality treatment. If single-pass beating is used, the aperture of the mesh should not be too small, otherwise the mesh will be easily blocked.

4. Centrifugal filtration: The centrifugal filtration of the fruit juice beverage production line needs to be completed by a horizontal screw centrifuge, and the principle of centrifugal force is used to separate the fruit and vegetable juice from the pulp. The slurry enters the centrifugal chamber of the drum through the central feeding pipe. Under the action of high-speed centrifugal force, the pomace is thrown onto the wall of the drum, and the pomace is continuously sent to the conical end of the drum by the screw conveyor for discharge. Outflow from the front end of the drum through the threaded gap.

5. Coarse filtration: The coarse filtration of fruit juice beverage production line is the process of removing larger particles or suspended particles dispersed in fruit and vegetable juice. In addition to the beating method, the fruit and vegetable juice obtained by other methods contains a large number of suspended particles. If the flesh fiber, peel, fruit stone, etc., their existence will affect the appearance quality and flavor of the product, and it needs to be removed in time. During the juice process, a vibrating screen is usually used for coarse filtration. Generally, the fruit and vegetable juice can meet the coarse filtration requirements through a 0.5-hole sieve. Clarification and filtration are required after coarse filtration of fruit and vegetable juices, and homogenization and degassing are required for cloudy juices and beverages with meat.

6. Adjustment and mixing of sugar and acid in fruit juice: The sugar-acid ratio of most fruit juice products is (13:1)-(15:1). Many fruits alone produce good crystalline juices, but they are better when combined with other varieties of fruit. Add appropriate amount of sugar and edible acid (citric acid or malic acid) to fresh juice

7. Vacuum degasser: There is a lot of oxygen in the juice produced by the juice beverage production line, which will destroy the Vc in the juice, and the oxygen will react with various components in the juice to deteriorate the aroma and color. The product is sprayed into a degassing tank with a vacuum of about 0.6 bar at a temperature of about 55°C, the product boils instantly, volatilizes the oxygen and aromatic gas contained in it, and then the aroma is condensed into a liquid state by a cooler and added back. In the product, the oxygen is directly exhausted.

8. Sterilization, UHT ultra-high temperature sterilization is used to sterilize the product.

9. Filling: Hot filling: 1. The rinse water is pure sterile water. 2. Hot filling is required to be above 85°C, and the net content of the filling is as small as 500. 3. After capping, the bottle mouth is rinsed with pure water, and there is no residual liquid. The capping requires an opening torque of 28. The finished product of the single-piece cap is opened. Torque (90-170) N.cm or (8-15) lbf.in Two-piece cap finished opening torque (110-226) N.cm or (10-20) lbf.in, no damage to the cap, no protrusion .

10. Secondary sterilization: Invert the bottle and pasteurize the sealed product. This is the sterilization of the pair.

11. Packaging: Label the product through a labeling machine or a sleeve labeling machine, and then use the inkjet printer to print the production date. Then use film packaging or carton packaging for 12 or 14 bottles. If the output is large, you need to use an automatic palletizer.